AC wiring is largely complete at this stage, and the core of the DC distribution system is also in place.

When we last left off with the electrical system, the batteries, panels, charge controller and inverter were wired up, but there was no AC distribution and the system was not live. Shortly after I returned from England, I flipped the switch on the system and have been using it ever since. Performance is good- I’m making over 2.0 KWh per day even as we approach the shortest day of the year, and managed 600 Wh yesterday, even though it stormed all day long and the sun never shined. Most days I have too much power, as I’m only running tools and LED lights off the bus at this time, so the charge controller completes its absorb cycle by 10 or 11 AM and then just floats for the remainder of the day and delivers only enough power to keep the batteries topped off.

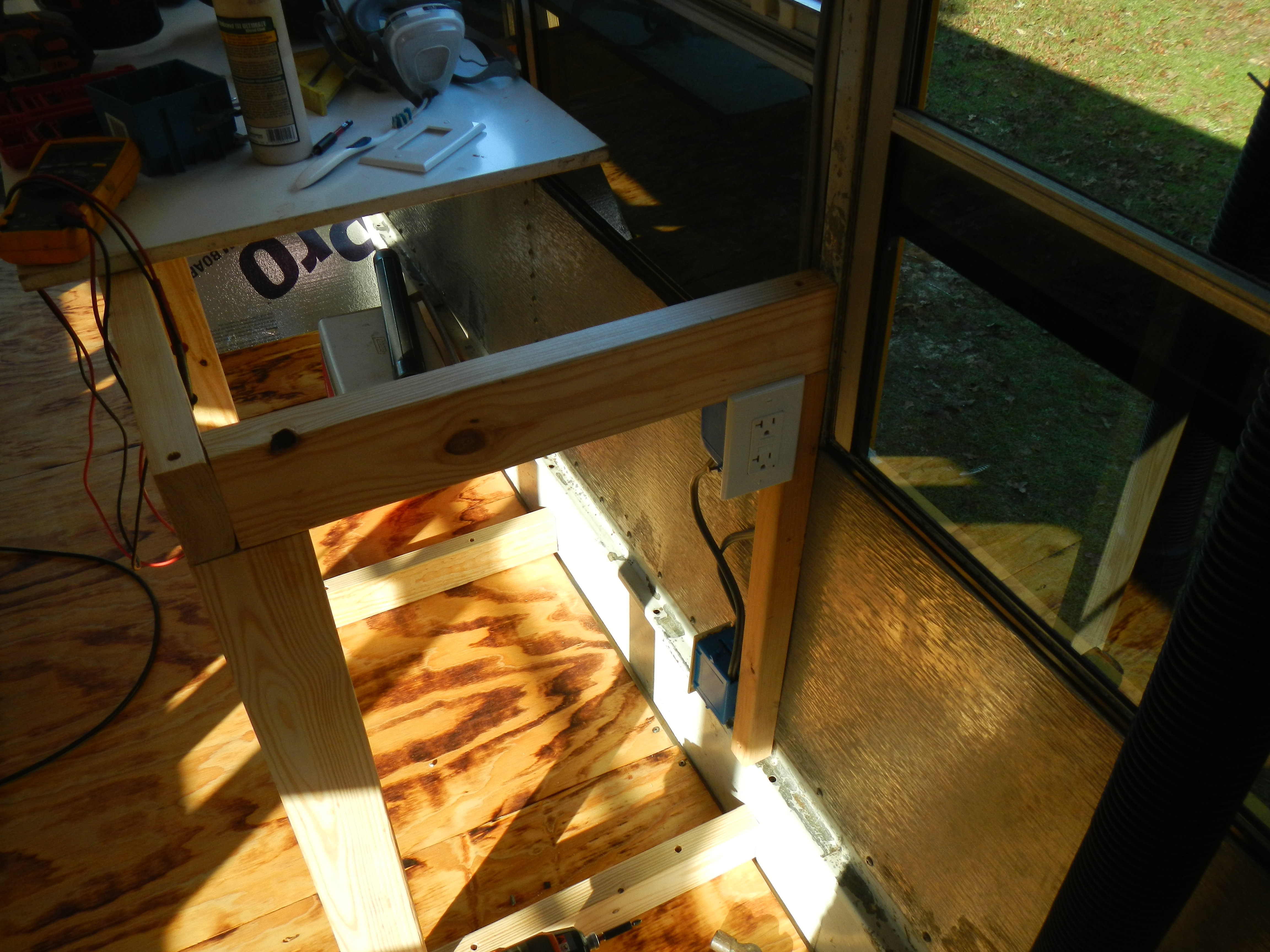

I initially installed only one outlet inside the cabinet and used extension cords, but once the bench and counters were framed out I ran wiring and installed outlets. I also put a door and a furnace filter on the cabinet, and wired up the exhaust fan to a switch on the side. With the filter and fan, I can cut and sand inside the bus without undue worry about sawdust clogging up the inverter and charge controller cooling systems.

The jump from the electrical cabinet to the rest of the bus is accomplished using flexible boat cable since the cabinet is suspended and the cables will be subject to persistent vibration. DC wiring is run throughout the bus using boat cable plus 16 and 18 GA speaker wire, while AC wiring uses 12 GA romex. I originally had mixed feelings about using romex due to the risk of work hardening and embrittlement, but all of the cable runs are well secured and amply protected (breakers, GFCI and AFCI) so I don’t anticipate any issues or risks for the lifetime of the bus.

Total outlets: 8 on left side of bus, 4 on right side of bus. Each side has its own dedicated 20A breaker. Left hand side will see primarily intermittent loads (blender, air compressor, laptop chargers) while the right hand side will power the refrigerator and any eventual air conditioning system.

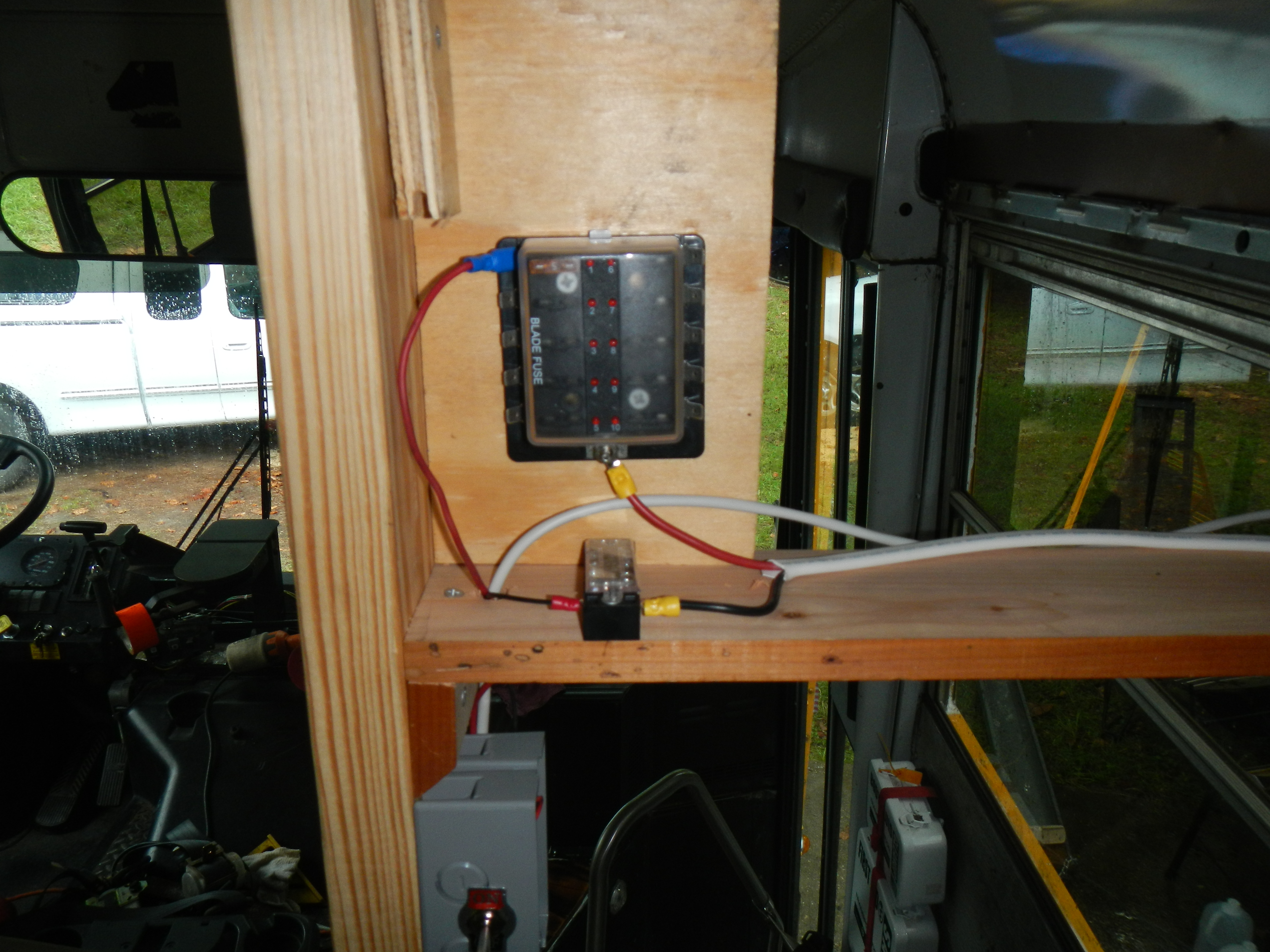

DC wiring is organized around two primary 12 GA distribution lines to the front and rear of the bus. Each can deliver 20A, which should be more than sufficient to power lights, sound system and any small 12V appliances. Protection comes in the form of 20A DC breakers between the batteries and distribution, and fuse panels between the distribution and ancillary loads.

Any heavy DC loads will get dedicated lines run at time of installation. Currently the only planned heavy load is the fresh water pump, which will live under the bed next to the tank.